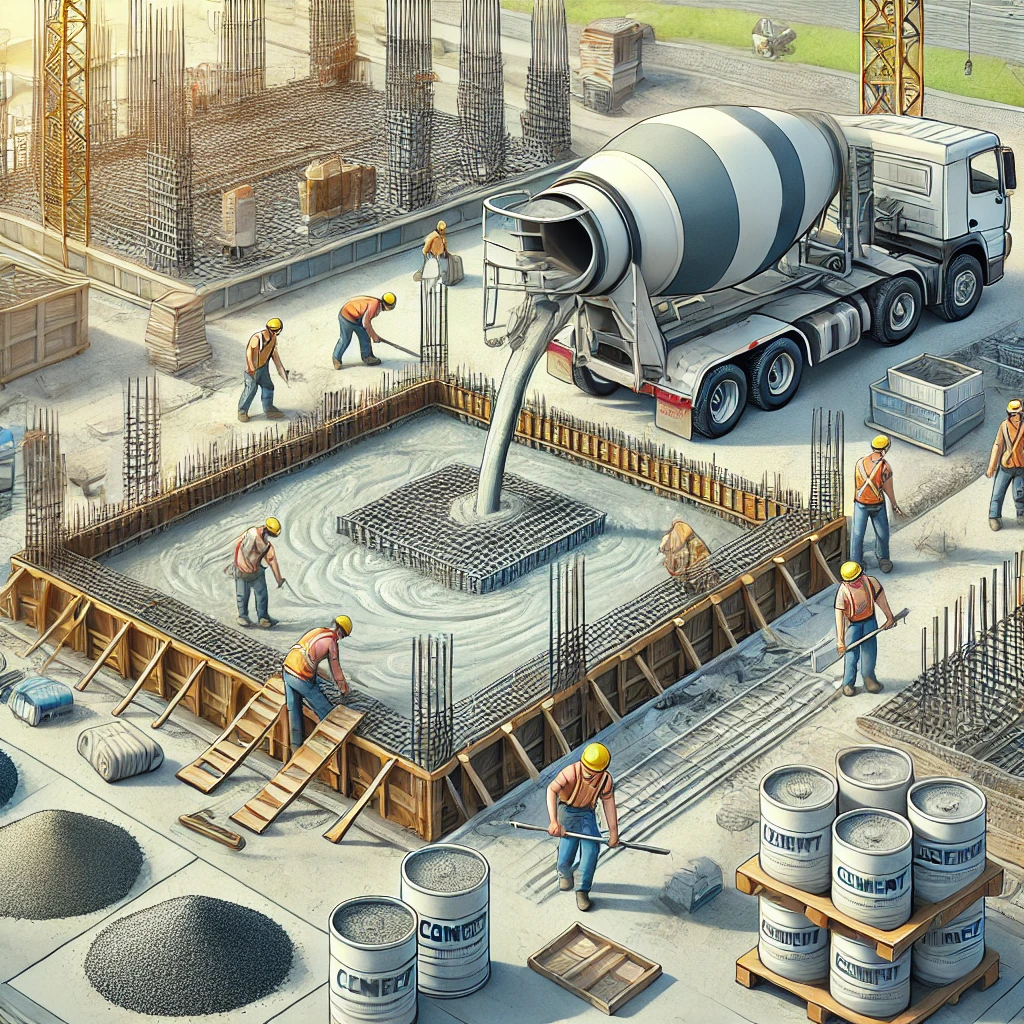

Concrete is one of the most essential and widely-used materials in construction, known for its durability and versatility. Made from a mixture of coarse aggregates like sand, gravel, crushed stone, or slag, and bonded with cement, concrete plays a vital role in everything from small home projects to large-scale infrastructure. For anyone interested in figuring concrete—whether for a DIY project or a major construction—understanding its composition, types, and the mixing process is key.

What is Concrete and How is It Made?

Concrete is essentially a mixture of water, cement, and aggregates. Cement, often Portland cement, acts as a binding agent that holds the aggregates together. This mixture hardens over time, a process known as curing. Properly mixed concrete is crucial for achieving the strength and longevity required for its intended application. Learn more about the types of concrete used in construction and their unique properties.

How to Figure Concrete: Quantities and Forms

For those who need to figure out how much concrete is necessary for a project, concrete can be bought in different forms. Smaller projects may use pre-mixed 60- or 80-pound bags available at hardware stores. For larger projects, ready-mix concrete can be delivered by specialized mixer trucks.

Accurately figuring concrete quantities is essential for cost efficiency and ensuring adequate material for the job. This involves calculating the volume of the area to be filled and understanding the strength requirements. You can refer to this concrete calculator to help estimate the amount needed for your project.

The Mixing Process: Achieving Strong Concrete

Mixing concrete correctly is key to its strength and uniformity. This involves the right balance of water, cement, and aggregate, as well as any specific additives for unique applications. Concrete is typically prepared as a viscous fluid to be placed into forms. The time-sensitivity of concrete means it must be used promptly before it begins to harden.

For certain projects requiring quick setting, high-strength concrete mixes are available. Alternatively, precast concrete products—such as walls or barriers—are often made in a factory environment, allowing for tighter control of the concrete’s strength and curing process. For guidance on mixing techniques, see this guide on mixing concrete.

Curing Concrete for Maximum Strength

Curing is the process by which concrete hardens and gains strength. Most concrete reaches around 90% of its final strength within four weeks, although it can continue to strengthen for up to three years. During the initial curing period, keeping the concrete damp enhances its strength. This can be done through methods like spraying compounds that retain water or using plastic wraps to create a moist environment. Submerging the concrete in water, a process called ponding, is also effective for optimal curing. You can find more curing methods in this guide to concrete curing.

Why Figuring Concrete is Crucial for Construction Success

Figuring concrete isn’t just about buying the right amount; it’s about choosing the right type, understanding the curing process, and knowing how to achieve the best possible strength. Whether you’re mixing concrete on-site or opting for precast forms, careful planning ensures that your concrete project will be durable and long-lasting.

With the correct calculations and an understanding of concrete’s curing process, figuring concrete becomes much easier, ensuring a strong, reliable foundation for any construction project. For more information, visit this comprehensive concrete project planning guide.